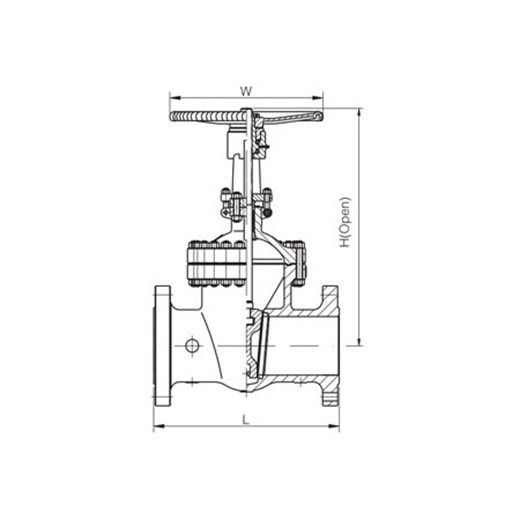

API600 Class 900 OS&Y Cast Steel Gate Valve

GAV701-900

Sharaxaada Alaabta

API600 Class 900 OS&Y Cast Steel Gate Valve waxaa inta badan lagu isticmaalaa warshadaha u baahan cadaadis sare iyo awood heerkul sare. Furayaashan waxaa sida caadiga ah loo adeegsadaa codsiyada sida soosaarka saliidda iyo gaasta, sifaynta, kiimikaad batroolka, korantada, iyo geeddi-socodka warshadaha halkaas oo baahida loo qabo xalal la isku halleyn karo oo adag ay muhiim tahay.

Qiimaynta Fasalka 900 waxay muujinaysaa in waalka loogu talagalay inuu u adkaysto cadaadiska ilaa 900 rodol halkii inji oo labajibbaaran (psi), taasoo ka dhigaysa mid si fiican ugu habboon jawiga dalbanaya halkaas oo xaaladaha cadaadisku ay joogaan. Intaa waxaa dheer, nashqada OS&Y (Outside Screw iyo Harqood) waxay bixisaa fududaynta dayactirka iyo tilmaanta muuqaal ee booska valve, sii wanaajinta ku habboonaantiisa codsiyada muhiimka ah.

Guud ahaan, Class 900 Cast Steel Gate Valve ayaa si aad ah loogu baahan yahay warshadaha u baahan waxqabad la isku halayn karo oo ay ku jiraan cadaadis adag iyo xaaladaha heerkulka.

Astaamaha

Dulmarka alaabta

Kala duwanaanta waxaa loo qaabayn karaa si ay ugu habboonaato codsigaaga, iyada oo la adeegsanayo dhismaha jidhka, agabka, iyo astaamaha kaalmaha ah ee la hagaajiyey si loo daboolo baahiyahaaga habsocodka. Iyada oo la aqoonsan yahay ISO 9015, waxaan qaadaneynaa habab nidaamsan si aan u hubinno tayada sare, waxaa laguu xaqiijin karaa isku halaynta wanaagsan iyo waxqabadka shaabadeynta iyada oo loo marayo nolosha naqshadeynta hantidaada.

Shuruudaha Farsamo

Naqshadeynta iyo Wax-soo-saarku waafaqayaan API 600

Cabirka Flange wuxuu waafaqsan yahay ASME B16.5

Cabbirrada wejiga ka wejiga waafaqayaan ASME B16.10

Tijaabada Waafaqsan API 598

Habka wadista: giraangiraha gacanta, qalabka bevel, koronto

Tilmaamid

| Magaca Qaybta | Qalab |

| Jirka | A216-WCB |

| Jeex | A216-WCB+CR13 |

| Bonnet Stud Nut | A194-2H |

| Bonnet Stud | A193-B7 |

| Jirrid | A182-F6a |

| Bonnet | A216-WCB |

| Kursiga danbe ee stem | A276-420 |

| biinanka isha | Birta Kaarboonka |

| Gacmo-gacmeed | Birta Ductile |

Xargaha badeecada

Xogta cabbirka

| Cabbirka | in | 2 | 21/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| L/L1 (RF/BW) | in | 14.5 | 16.5 | 15 | 18 | 24 | 29 | 33 | 38 | 40.5 | 44.5 | 48 | 52 | 61 |

| mm | 368 | 419 | 381 | 457 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | 1549 | |

| L2 (RTJ) | in | 14.62 | 16.62 | 15.12 | 18.12 | 24.12 | 29.12 | 33.12 | 38.12 | 40.88 | 44.88 | 48.5 | 52.5 | 61.75 |

| mm | 371 | 422 | 384 | 460 | 613 | 740 | 841 | 968 | 1038 | 1140 | 1232 | 1334 | 1568 | |

| H (FURAN) | in | 19.62 | 21.5 | 22.5 | 26.62 | 35.5 | 43.5 | 53 | 60 | 74.88 | 81 | 87 | 101 | 104 |

| mm | 498 | 547 | 573 | 678 | 900 | 1103 | 1345 | 1525 | 1900kii | 2055 | 2215 | 2565 | 2640 | |

| W | in | 10 | 10 | 12 | 18 | 20 | 24 | 26 | 29 | 32 | 32 | 36 | 38 | 40 |

| mm | 250 | 250 | 300 | 450 | 500 | 600 | 640 | 720 | 800 | 800 | 950 | 950 | 1000 | |

| WT (Kg) | RF/RTJ | 74 | 101 | 131 | 172 | 335 | 640 | 1100 | 1600 | 2250 | 2850 | 3060 | 3835 | 4900 |

| BW | 54 | 78 | 105 | 135 | 260 | 515 | 920 | 1380 | 2010 | 2565 | 2485 | 3250 | 4065 |